While electrical tape is a common and easy way to bind electrical cables together, it is not always the best option. For example, thermoset and thermoplastic are two materials that are designed specifically for insulating wires.

Thermoset is a hard, durable material that can withstand high temperatures and is used in applications where the wire may be exposed to extreme conditions. Thermoplastic is a softer, more pliable material.

Electrical tape is not as durable as thermoset or thermoplastic and should only be used in low-temperature applications or for temporary repairs. Thermoset and thermoplastic are the two main types of insulation used to cover electrical wires and other components to protect them from damage and prevent short circuits.

Let’s look a closer look at materials that you can use as alternatives to electrical tape for insulating wires.

Should You Use Electrical Tape?

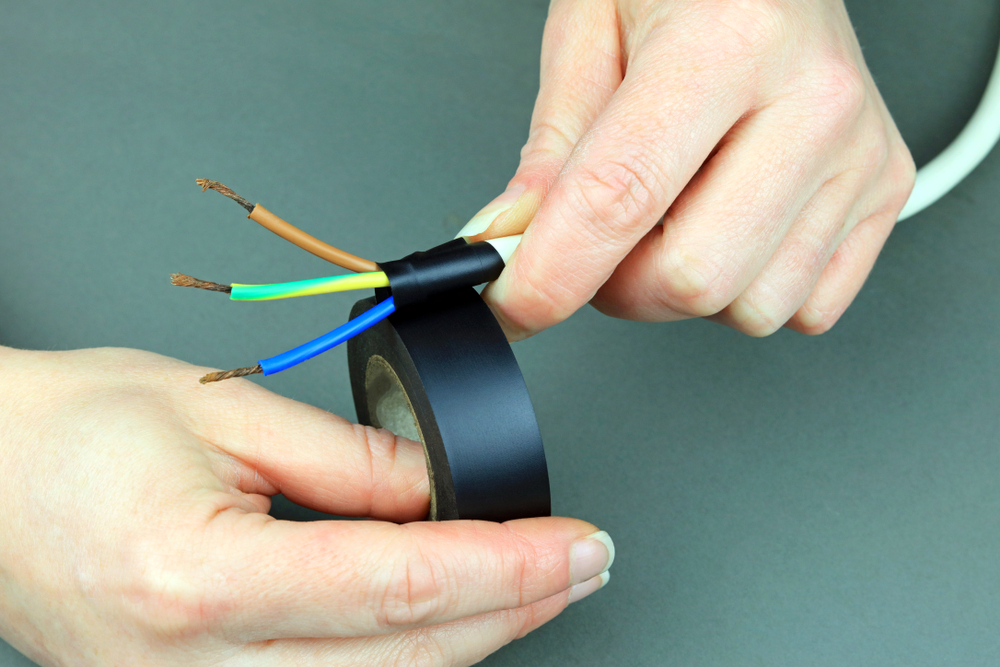

Electrical tape is an insulator that protects against electrical hazards. Typically, the tapes used for most electrical applications include varnished cambric, mastic, rubber, and vinyl.

Electricians mainly use black tape to insulate wires and other components, as well as to bundle them together. Meanwhile, other colors indicate the wiring phase and voltage level. They’re also called phasing tapes.

You should use electrical tape in the following situations:

- You need a budget solution since electrical tape is cheaper than velcro straps.

- You want to leave a minimal sticky residue.

- The wires need to be held together without making them too tight to prevent breathability.

While electrical tape is a convenient and easy way to bind electrical cables together, it is not always the best option. In fact, in some cases, it can actually be dangerous.

For example, if the tape is not applied correctly, it can create a gap in the insulation, allowing electrical current to arc across the gap and cause a fire.

In addition, electrical tape is not very durable and can easily be damaged by heat, cold, or abrasion. Therefore, it is not recommended for use in high-temperature or high-voltage applications.

It is one of the most common bindings used for electrical cables. When applied properly, it should not conduct electricity.

Alternative 1: Polyethylene Thermoplastic

Polyethylene thermoplastic is made from a polymer of ethylene, which is a naturally occurring gas. It is lightweight, durable, flexible, and has excellent chemical resistance.

Polyethylene is also non-toxic. Thus, it is often used in food packaging, medical devices, and other products that come into contact with humans.

Since it offers high-power loss protection, wires coated in this material are often used in underground applications. Ideally, polyethylene is resistant to corrosion, UV radiation, and water absorption. It can be molded into various shapes and sizes depending on the application.

Advantages

- Doesn’t let the wires leak current

- Covers high-frequency signal carriers well

- Has a high degree of impact resistance

- Resistant to most chemicals

Disadvantages

- Prone to insulation shedding

- Produces poisonous gas when combusts

Cost

You can get a meter of polyethylene thermoplastic for $1.89 to $2.03. The price depends on the thickness of the material.

How to Use

You can use this material to coat the wires by using a heat gun. The process is simple and doesn’t require any special skills.

First, cut the polyethylene thermoplastic into strips slightly wider than the wires you want to cover. Next, use a heat gun to heat the plastic until it’s soft and pliable.

Then, wrap the heated plastic around the wire. Make sure that the entire surface of the wire is covered.

Alternative 3: Chlorinated Polyethylene Insulation

Thermoplastic elastomer insulation offers good dielectric and mechanical performance, flexibility, resilience, and resistance to water and ultraviolet light. It can be used as an insulation material for medium- and high-voltage cables, plus for some special applications such as solar power systems.

Chlorinated polyethylene (CPE) is a highly chlorinated derivative of polyethylene. The degree of chlorination can vary between 30 and 70 percent by weight. The level of chlorination influences the physical, electrical, and chemical properties of CPE.

CPE has very good electrical insulating properties and is used in medium voltage applications such as underground power cables and building wires and high voltage applications such as transmission cables.

Advantages

- Weather and heat resistant

- Low-cost

- Environment-friendly compared to CSPE (cross-linked polyethylene)

Disadvantages

- High permeability to gas

- Poor self-viscosity

Cost

A single CPE cable can cost $0.4 to $10.5. It covers a meter of wire.

How to Use

A CPE jacket refers to a layer of material that is applied over the insulation of an electrical conductor, usually to protect it from the environment. The most common type of CPE jacket is black and is made from chlorinated polyethylene.

CPE jackets are also used on fiber optic cables and telephone wires. The jacket is extruded over the core and buffer of the fiber optic cable and over the insulation of the telephone wire.

The CPE jacket protects the conductor from abrasion, water, and other environmental factors.

Alternative 3: EPR Insulated Cables

Consider purchasing cable that is already pre-insulated with EPR or ethylene propylene rubber.

EPR (ethylene propylene rubber) insulation is a type of synthetic rubber insulation that offers superior electrical properties and resistance to heat, chemicals, and environmental conditions. It is often used in electrical applications where cost and weight are important considerations.

EPR is made from a combination of ethylene, propylene, and diene monomers. The result is an elastomer that has excellent electrical properties and flexibility over a wide temperature range. It also has excellent resistance to oil, ozone, and electrical tracking.

EPR insulation is made from a copolymer of ethylene and propylene, which gives it excellent flexibility and resistance to degradation. The insulation is also flame retardant and has a low smoke generation rate.

Advantages

- Thermal range from -55°C to 150°C

- Weather and ozone resistance

- Flame retardant

- Low smoke generation rate

Disadvantages

- Poor resistance to oil and solvents

- Relatively high cost

Cost

The regular price for EPR insulation starts at $8.34 per foot.

How to Use

EPR insulation is available as both solid and stranded wire. Solid wire is used where space is limited, like electronic equipment. The stranded wire is more flexible and is used in applications that require flexibility, such as electrical motors.

When installing EPR insulation, it is important to use the correct tools and techniques to avoid damaging the insulation. Strippers designed for use with EPR insulation are available in most electrical supply stores.

What Not To Use As a Electrical Tape Replacement

Although there are many alternatives to electrical tape, there are some materials you should not use for insulating wires. For one, duct tape is not a good insulating material because it dries out quickly and becomes brittle.

It can cause the tape to crack and allow electrical current to pass through, which can be dangerous. Duct tape is also not very sticky, so it may not stay in place for long.

Likewise, don’t use masking tape or any other type of paper tape. These materials do not have the same insulation properties as electrical tape and can break down quickly.

Using scotch tape or aluminum foil can create a bigger problem than it solves. Both materials are not intended to be used as insulators, and using them can cause a fire hazard.

Finally, avoid using any kind of adhesive that is not rated for electrical use. Adhesives not meant for electrical wiring can create a fire hazard, so always use the right material for the job.