With recent advancements in the home insulation industry, there are now many more options available to homeowners than ever before. One of these options is vacuum insulation panels or VIPs.

Vacuum-insulated panels have a higher thermal resistance than most other types of insulation. They are also much thinner, making them ideal for use in tight spaces or areas where conventional insulation would be challenging to install.

Here’s an overview of vacuum-insulated panels, their advantages, and their mechanism of action. We also explain where you can use vacuum insulation panels.

What Is a Vacuum Insulated Panel?

A vacuum insulated panel is a type of panel used to insulate and protect against heat loss. It is made up of two layers of metal with a layer of insulation in between.

The panel is placed over an area that needs to be heated or cooled, and the heat or cold is transferred to the panel. The transfer of heat or cold can be used to keep an area at a constant temperature or to raise or lower the temperature slowly.

Vacuum insulated panels consist of the following:

- Membrane Walls: They prevent the entry of air into the panel.

- Silica or Aerogel Panel: There’s a highly-porous and rigid panel of perlite, glass fiber, fumed silica, or aerogel that’s used to insulate the panel. It also provides support to the membrane walls.

- Getters: Getters are materials that absorb gasses. They are used to keep the panel free of air and moisture. These chemicals can be in the form of powder, granules, or strips.

The panel is sealed with a sealant that prevents air and moisture escape. As a result, vacuum insulated panels have a higher thermal resistance or lower thermal conductivity than conventional insulation. Typically, you can expect VIPs to have a thermal conductivity of 0.004 W/(m·K).

Meanwhile, polyurethane panels have a thermal conductivity of 0.024 W/(m·K), while mineral wool thermal conductivity is 0.044 W/(m·K).

Therefore, VIPs are better at insulating than conventional insulation materials like fiberglass and rock wool. Moreover, VIPs don’t allow convection or conduction, providing excellent heat flow resistance.

Advantages of Vacuum Insulation Panels

Vacuum insulated panels have plenty of advantages. Here are some of them:

High R-value

For starters, they have a very high R-value per inch, meaning they are great at insulating against heat loss. R-value indicates how well a material can resist heat flow; the higher the number, the better.

With an R-value of R-25 to R-30, vacuum insulation panels have one of the highest R-values of any type of insulation on the market today. It makes them ideal for use in areas where you want to keep heat in, such as in a home or office.

Thin Build

Since they are so thin, vacuum insulation panels can be used in various applications where space is limited. For example, they can insulate walls, floors, ceilings, and even doors and windows.

Lightweight

Another advantage of vacuum insulation panels is that they are very lightweight. That makes them easy to transport and install.

How Does Vacuum Insulation Panel Work?

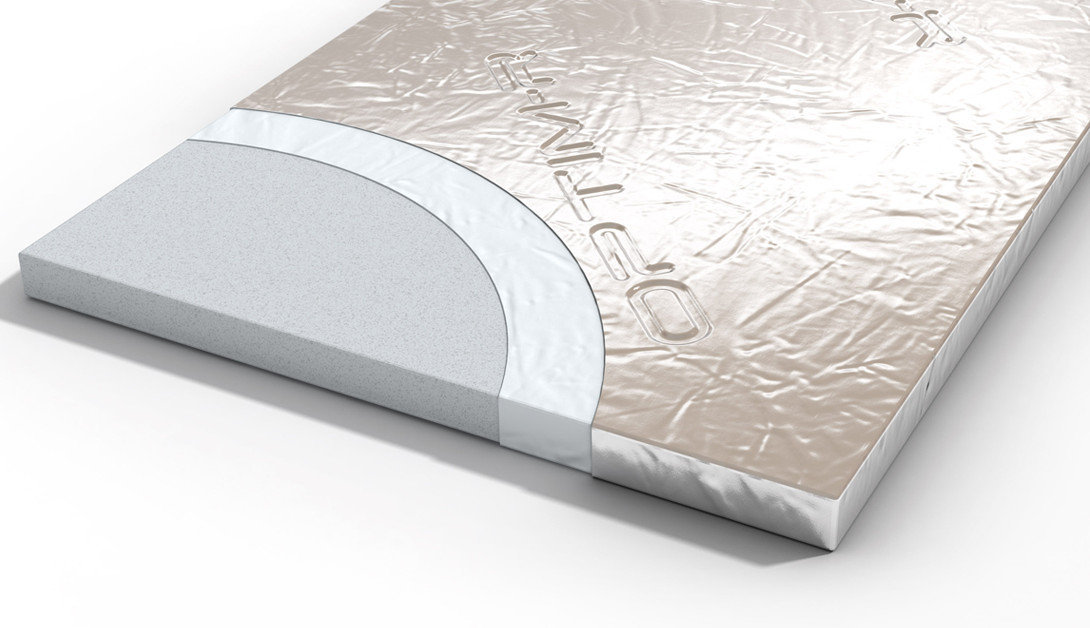

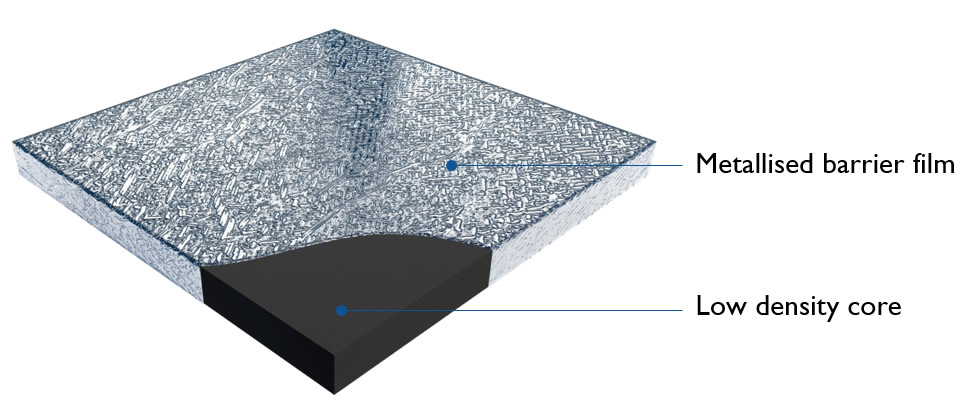

The core of a vacuum insulated panel is made of fumed silica in a pressed powder form. The material is placed in the mold and compacted under high pressure to form a monolithic block.

Once the block is formed, it is cut into thin sheets and used as the core material for the vacuum-insulated panel. Finally, the manufacturers seal it under vacuum using a gas-vapor tight film.

Since there’s a vacuum, there’s no chance of gas conduction. It’s possible because the molecules are far apart, and there are no free electrons to carry the heat.

The lack of free electrons also eliminates convection within the panel. So the only way heat can move through the panel is by radiation.

The manufacturers add reflective material to the panel’s surface to further reduce heat transfer by radiation. The result is a highly effective insulation material.

Vacuum insulated panels can last for up to 25 years. Their long lifespan is due to their resistance to heat loss and moisture damage. As a result, VIPs are an excellent choice for construction projects that require long-term insulation performance.

Where Can Vacuum Insulated Panels Be Used?

Vacuum insulated panels can be used in many applications, including:

- Insulation for walls, ceilings, and floors

- Thermal storage (e.g., for solar heat)

- Refrigeration and cryogenics

- Automotive industry

- HVAC

- Building envelope

In a residential setting, they can be used to insulate walls, ceilings, and floors. In addition, many green home prototypes incorporate VIPs into their design to help reduce the home’s overall energy consumption.

Vacuum offers a better heat blockage compared to conventional insulation materials. VIPs are also much thinner, allowing for more home space.

In commercial buildings, VIPs can insulate the exterior walls and roofs. They can also be used in interior partitions, HVAC ductwork, and around piping.

When To Use Vacuum Insulation Panels?

When you have to improve the thermal performance of a building, it’s often hard to fit extra insulation without compromising the space inside. That’s where VIPs come in handy – they can be used in areas where traditional insulation materials would be difficult to install.

More importantly, vacuum insulated panels can fit difficult areas, such as balconies and dormer windows, often left uninsulated due to their tricky design. So, if you don’t want to alter a building’s design but still need to make it more energy-efficient, VIPs are the way to go.

How Much Does a Vacuum Insulation Panel Cost?

Typically, you can expect to pay anywhere from $10 to $12 per square foot for a good quality vacuum insulation panel.

The price will vary depending on the panel’s brand, size, and thickness. However, remember that the initial investment will pay off in the long run since you won’t have to spend as much on your energy bills.

Besides the cost of the panels themselves, you also need to consider the following expenses:

- Installation Costs: Since vacuum insulation panels need to be installed by a professional, you will need to factor in the installation cost. It can range anywhere from $200 to $1,000, depending on the size and complexity of the project.

- Permits: You may need to obtain a permit from your local municipality before you can install the panels. The permit cost will depend on your location, but it is typically a few hundred dollars. You should research the regulations for your locality beforehand.

- Equipment: You will need to purchase or rent the equipment required to install the panels. It includes a vacuum pump, vacuum chamber, and installation kit.

Generally, there aren’t any hidden costs associated with vacuum insulation panels. However, it’s always a good idea to consult with a professional to get an accurate estimate of the costs involved in your project.

There are two ways to approach the purchase of vacuum insulation panels. First, if you have some know-how, you can purchase the panels and equipment online or from a local home improvement store.

Or, you can leave the hassle to the professional you hire for installation and let them purchase the materials needed for the project. If you decide to go the DIY route, do your research and buy high-quality products to ensure the best results.