Foam board insulation comes in an array of different thicknesses for a range of applications and practical settings designed to give maximum flexibility to installers on new or retrofit projects.

What happens when the R-value, or the dimensions for your project don’t match what is on offer at the supplier? In this scenario there will be calculations to be made based upon many factors, not least of all installation time.

You can successfully stack foam board insulation to achieve the level of energy efficiency required. Using the right combination of material in the proper way you can hit those targets.

Here’s our guide to stacking foam boards for the best results.

How Much Rigid Foam Board Can You Stack?

To some extent it depends on which part of the house is to be insulated, and which material to use, as to what is the best approach to stacking foam board insulation. At some point the benefit of the R-value produced by stacking will run out.

Diminishing returns mean that eventually it becomes pointless to fit any more insulation. In the Southern states of the USA, it is recommended that you do not over-insulate in case air becomes trapped inside the house during the summer months.

When upgrading a home, which already has a level of insulation, then adding more foam board to an existing installation is a possibility. However, if you fit too much insulation, it may end up costing you more than you might save on your energy bill.

It’s worth taking the time to work out the optimal level of insulation for your house, in your climate zone, subject to your local codes.

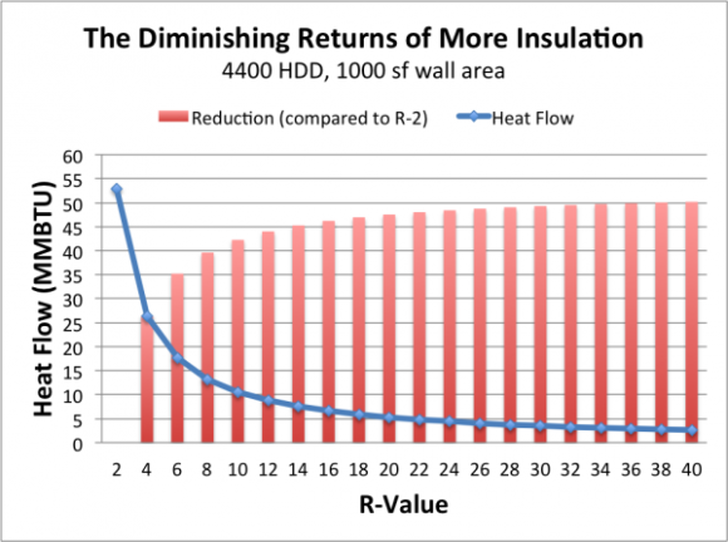

Energy consultant Dr Allison Bailes developed the graph below, doing the math so you don’t have to.

The graph shows how quickly even a small amount of insulation can be effective, slowing heat flow and maintaining comfort levels. When you get to the R-value recommended by the building code, it is wiser to perhaps consider other ways to make energy savings.

You can see quite clearly that the difference between R-10 and R-20 is very noticeable, making early gains and delivering payback for the investment in insulation quite quickly. However, following the curve and doubling again to R-40 will only yield half the previous improvement in terms of heat flow.

Which Boards are Better for Stacking

Space, time, and budget all play a part. The less space you have to use, then a higher R-value board will be required to achieve the required result.

An expanded polystyrene foam board that is rated R-4/inch can be installed in any number of layers up to the depth recommended by local codes. But you will need more of it to achieve a higher level of insulation. Extruded polystyrene has slightly better insulating performance, averaging R-5.

Polyisocyanurate board has the highest rating of R-8/inch, providing greater effectiveness for the smaller available depth. If you are insulating the exterior walls of a house then the thinner the insulating layer means that there will be fewer issues with siding fixings, and less siding material required (because the exterior dimensions of your house will be smaller).

The Best Places to Stack Foam Board Insulation

External Walls

There is a clear advantage to stacking foam board insulation when you are insulating the external walls of a house, which is that you can stagger the joints, ensuring a better air seal. You could also tape the joints on the first layer to enhance the seal further.

When working on the external walls you should ensure that the boards are fitted tight together and that any gaps are closed up using a can of spray foam. No amount of insulation will work well if the house envelope is not airtight. Taping the joints on both layers will help ensure the long term effectiveness of the external air seal.

With other external board systems, such as EXP, or Styrofoam boards, very often the edges are made to interlock, so this is less of an issue. However, even when stacking interlocking boards joints should still be staggered for maximum efficiency.

Internal Walls

It’s worth noting that if you already have a vapor barrier then using foil faced PIR board in this location is not the best choice as you could end up with a double vapor barrier situation, which may cause mold and damp problems.

Best practice is to fit the insulation board as tight as possible between the wall studs, using spray foam or caulk to close any gaps.

Recommended read: How To Install Foam Board Insulation On Interior Walls

It is technically possible to fit two layers of PIR board with a gap between the two faces, which should, in theory, contribute to the slowing of thermal movement and increasing the R-value of the wall. However, ensuring the required air seals in multiple bays across an entire wall are perfect is probably not worth the extra time and effort required unless you are investing in a total passive home system.

It may be preferable to mix and match insulation types in the internal walls. Sometimes batts and boards can be a good combination.

Attics

Insulating the attic is a no-brainer, and unless your house is very old, it probably already has some level of existing insulation between the ceiling beams. You can use foam board in conjunction with other forms of insulation, but you must take care not to crush loose-fill or fiber insulation.

The minimum rating for insulating an attic space varies according to climate zone. In the South it is R-38, while in the North the minimum requirement is R-49. The code states a max R-value of 60 as the top range of what could be needed, but it is better to look at individual buildings and their climate setting within the zone.

Recommended read: How to Install Attic Insulation Over Existing Insulation

R-60 is set as the maximum as it is the point of diminishing returns. The cost of material to insulate beyond this point would not be recuperated by further energy savings. R-60 achievable with 8 inches of polyisocyanurate board (two 4-inch boards) and would be simpler to fit than 16 inches of polystyrene.

Crawl Spaces and Basements

In a cold or maritime climate, it’s likely that the fiberglass insulation fitted between the floor beams will be water damaged simply due to the base humidity in this area. Upgrading this insulation is sensible, but again there are limits to what the code recommends.

Recommended read: Should You Insulate Your Basement? Costs and Considerations