When it comes to home insulation, there are two main choices; spray foam for its DIY abilities and blown insulation for its cheap yet effective nature. However, these insulating materials are not equal. Which one is the best option for you?

Blown-in insulation may be cheap for small spaces, but its price adds up quickly in large amounts. On the other hand, spray foam can have a more complex installation process but may be more effective for your needs in the long run.

What is the ultimate difference between these two methods of insulation? What kinds of blown insulation are available for public use? Can you install either of these methods yourself, or do you need to hire a professional?

Learn everything you need to know about spray foam and blown insulation to make the best possible decision for your home.

Spray Foam vs Blown-In: Overview

There are three main products you should consider here.

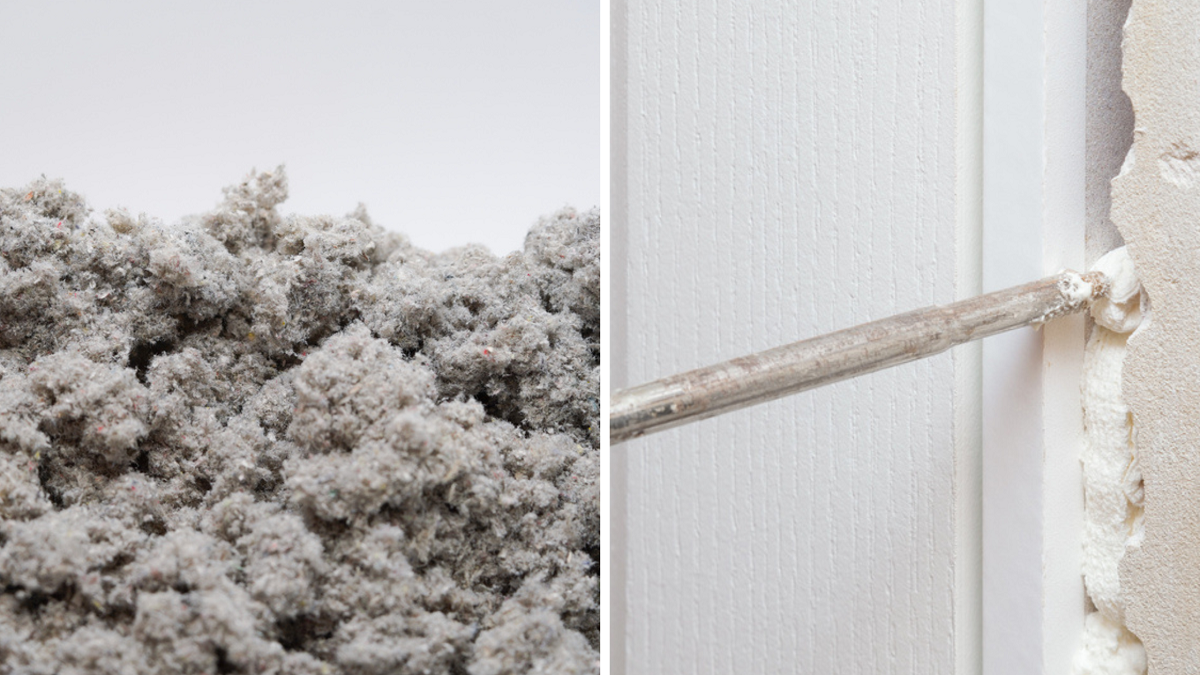

Spray foam is a foam insulating and sealing material, with many varieties readily available in any home improvement store.

Depending on the variety, spray foam can expand up to 30 or 60 times its original liquid size, though, with open cell insulation, this is multiplication factor is only around three.

Blown-in insulation is typically available in two materials, cellulose and fiberglass.

Cellulose is an insulating material composed primarily of recycled material, typically treated paper fibers.

On the other hand, fiberglass insulation features a composition of minuscule glass fibers.

Types Of Blown-In Insulation

Fiberglass Blown-In Insulation

Fiberglass insulation is a trusted and traditional method of insulation. With blown-in fiberglass insulation, you can easily insulate an attic, though the addition of netting and adhesives can help you insulate unfinished walls and ceilings from above.

Cellulose

Cellulose is a less-common method of insulation but rivals fiberglass in versatility. Typically, blown-in cellulose sits on the floor of your attic, but a variety known as ‘dense-packed’ can insulate your ceilings and walls with netting or an adhesive.

Spider Insulation

Spider insulation is essentially blown-in fiberglass insulation.

However, spider insulation can in some circumstances behave similarly to spray foam insulation due to its interlocking fiber technology.

The use of spider insulation does not require any netting or adhesives to remain in place in any small space since the fibers are interlocked in a web-like pattern (hence its name, spider insulation).

Advantages of blown-in insulation:

- Blown-in insulation is a far more economically viable option for insulation than spray foam.

- Blown-in insulation is superior against spray foam in a horizontal environment.

Disadvantages:

- Compressing your blown-in insulation, such as stepping on it, can reduce its R-value, unlike the relatively rigid form of spray foam.

- Unlike spray foam, blown-in insulation, particularly cellulose, is prone to settling. Settling, like compression, reduces the R-value of your insulation.

- Some forms of blown-in insulation, such as untreated cellulose, can burn quickly. However, both cellulose and fiberglass can withstand significant temperatures, especially when treated with fire retardants.

Types of Spray Foam Insulation

Open-cell spray foam

Open-cell spray foam is a spongy, flexible form of spray foam insulation that is mildly water-permeable. Open-cell spray foam uses air to create small, insulating pockets.

Any form of spray foam, but particularly open-cell spray foam, is perfect for attics, rim joists, and any crawl spaces in your home.

Closed-cell spray foam

Closed-cell spray foam is a high-density insulating material that utilizes gasses to expand and form a rigid coating.

While closed-cell spray foams are also exceptional for home use, many commercial projects, RVs, and barns utilize closed-cell insulation.

Advantages of spray foam insulation:

- Spray foam forms an air barrier, near-completely preventing airflow where blown-in insulation fails to do so.

- Small cans of spray foam are readily available for DIY projects around your house, such as insulating electrical outlets or window and door frames.

- Spray foam typically offers a higher R-value than blown-in insulations at comparable thicknesses.

- No insulation does well against water, but spray foam is better to install in humid environments than blown-in insulation.

Disadvantages:

- Spray foam can be challenging to install in humid environments, as it may take on water before curing.

- A single can of spray foam to insulate a few electric outlets is cheap, but full spray foam insulation is one of the most expensive insulating materials available.

- Spray foam can be highly toxic to handle, requiring specialized protective gear.

- Some forms of spray foam insulation are highly flammable and toxic when they burn, although their fire-resistant qualities often depend on the brand.

R-Value Comparison: Spray Foam vs Blown Insulation

The R-value of insulating material is a vital aspect to consider when choosing your new insulator. This R-value determines how effective your insulator is at maintaining temperature.

By maintaining a constant climate, a higher R-value means that your HVAC system consumes less energy to reach your desired temperature, ensuring that your home is energy-efficient and lowering your utility bills.

Open-cell spray foam has an average R-value of R-3.8 per inch, while closed-cell averages R-7 per inch. This number may seem low, but consider that spray foam expands to several times its initial size.

On the other hand, cellulose insulation averages around R-3.5 per square inch while fiberglass insulation fares at R-2.5.

Ultimately, when looking at the R-value and energy efficiency of these insulators, spray foam walks away with a victory.

Cost Comparison

When it comes to cost, spray foam is in an odd position; it is both the most expensive and cheapest option in this comparison.

If insulating small spaces, such as electrical outlets, windows, or door frames, a few cans of spray foam are the cheapest option by far.

On the other hand, full-fledged home insulation of spray foam can be costly. On average, you will pay $2,500 for professionals to install full spray foam, or you can do it yourself at around $420 for 200 square feet, that’s a little over $2.10 per square foot.

However, depending on the size of your home, insulating costs can reach well over $4,000.

Blown-in insulation is relatively cheaper. Starting at $0.88 per square foot, you can insulate your home with fiberglass for as little as $800.

However, cellulose insulation is slightly more expensive than fiberglass insulation. At around $1.20 per square foot, you can expect to pay an average of $1,500 for a cellulose installation, including labor costs.

Unfortunately, material and labor costs are not the only price factors to consider.

Blown-in insulation requires occasional maintenance, when your insulation settles, you will require a new layer. A new layer of insulation costs just as much as your initial installation, roughly every 20 to 30 years.

On the other hand, unless your home experiences significant damage, spray foam insulation requires very little maintenance and experts estimate that it can last for up to a century. It may be more expensive to initially install, but you save plenty of money in the long run.

If you’re looking for a cheap, upfront installation charge, blown-in insulation is your best option. If you want to save money in the long term, consider spray foam.

Installation Process Comparison

Nobody wants a complicated installation process. Unfortunately, due to the complicated and often toxic nature of insulation, it is a fact we must deal with.

You can DIY spray foam insulation in small areas as long as you have the proper protective equipment; canned spray foam does not offer much toxicity as long as you treat it with caution.

However, full spray foam insulation is highly toxic when curing. Professionals wear full-body protective gear to install multiple layers with specialized equipment on any wall, ceiling, or floor.

If you have the time and the materials, you can easily DIY blown-in insulation. The material is not particularly expensive; however, the equipment can be. Blowers and vacuums are not cheap, but you might find rentals at your local hardware store.

If you want an easy, safe install with minimal toxicity over its lifespan, consider spray foam.

Safety Comparison

You want to keep your home as safe as possible for any occupants. Which of these materials is safest?

During installation, spray foam can be incredibly toxic. You must allow it several days to cure. As a petroleum-based material, its curing process can cause headaches, nausea, or even cancer.

Certain varieties of spray foam, particularly those containing formaldehyde, are known carcinogens. Thankfully, after spray foam has cured, it stops emitting toxic gasses.

However, blown-in insulation is not exempt from safety issues.

Cellulose insulation lacks irritating fibers, but the glass fibers of fiberglass can cause severe irritation on contact, including your skin, eyes, mouth, and lungs. When installing or handling blown-in fiberglass insulation, you must wear protective equipment.

Blown-in insulation also typically features formaldehyde as a bonding agent, though in trace amounts. This formaldehyde does not go away like in spray foam.

Additionally, blown-in insulation is not waterproof. If cellulose or fiberglass gets wet, it can foster mold, mildew, or pest growth that can affect your health.

If handled improperly, both insulators can cause serious health issues, but many of spray foam’s health hazards cease after it cures.

Applications

Typically, both insulation methods are ideal for similar spaces. Spray foam insulation is ideal for attics, crawl spaces, and basements due to its waterproof abilities that can prevent a buildup of humidity during rainy seasons.

Similarly, blown insulation is an excellent choice for attics due to its light, potentially aesthetically-pleasing nature. However, installing blown insulation in unventilated areas is not a wise decision due to its tendency to harbor mold and mildew.

Is Spray Foam Insulation Better Than Blown-In Insulation?

Ultimately, no, spray foam is not inherently better than blown-in insulation. Both methods of insulation have advantages over the other. Spray foam may be a better insulator and potentially healthier, but it is far more expensive and complicated to install than blown-in insulation.